Description

|

||||||||||||

|

NOTE: 1.The liquid viscosity of the reaction is more than 10000 viscosity, and the deceleration motor is recommended. The machine comes with a non-deceleration motor. 2. This equipment is a fragile product, please handle it carefully when using it. 3. When using vacuum grease on rotatable parts such as glass cock or feeding tube, please choose a smooth and viscous brand. 4. Please apply the soft vacuum grease evenly and thinly on the valve core, so that the grinding port is fully matched. 5. After long-term use, the grinded parts where vacuum grease has been applied will oxidize or harden the grease, which may cause difficulty in rotation or stickiness of the grinded parts. Therefore, before the grease hardens, please regularly remove the parts and wipe off the grease on them with a paper towel, and then use toluene and xylene and other solvents to carefully wipe clean. After the solvent has completely evaporated, re-apply new vacuum grease. 6. If the grinding mouth has been tightened or stuck, forcibly disassembling at this time will cause the glass to break, which is very dangerous. When sticking occurs at the grinding mouth, please use heating (hot water, blowtorch) to soften the cured vacuum grease before disassembly. |

||||||||||||

|

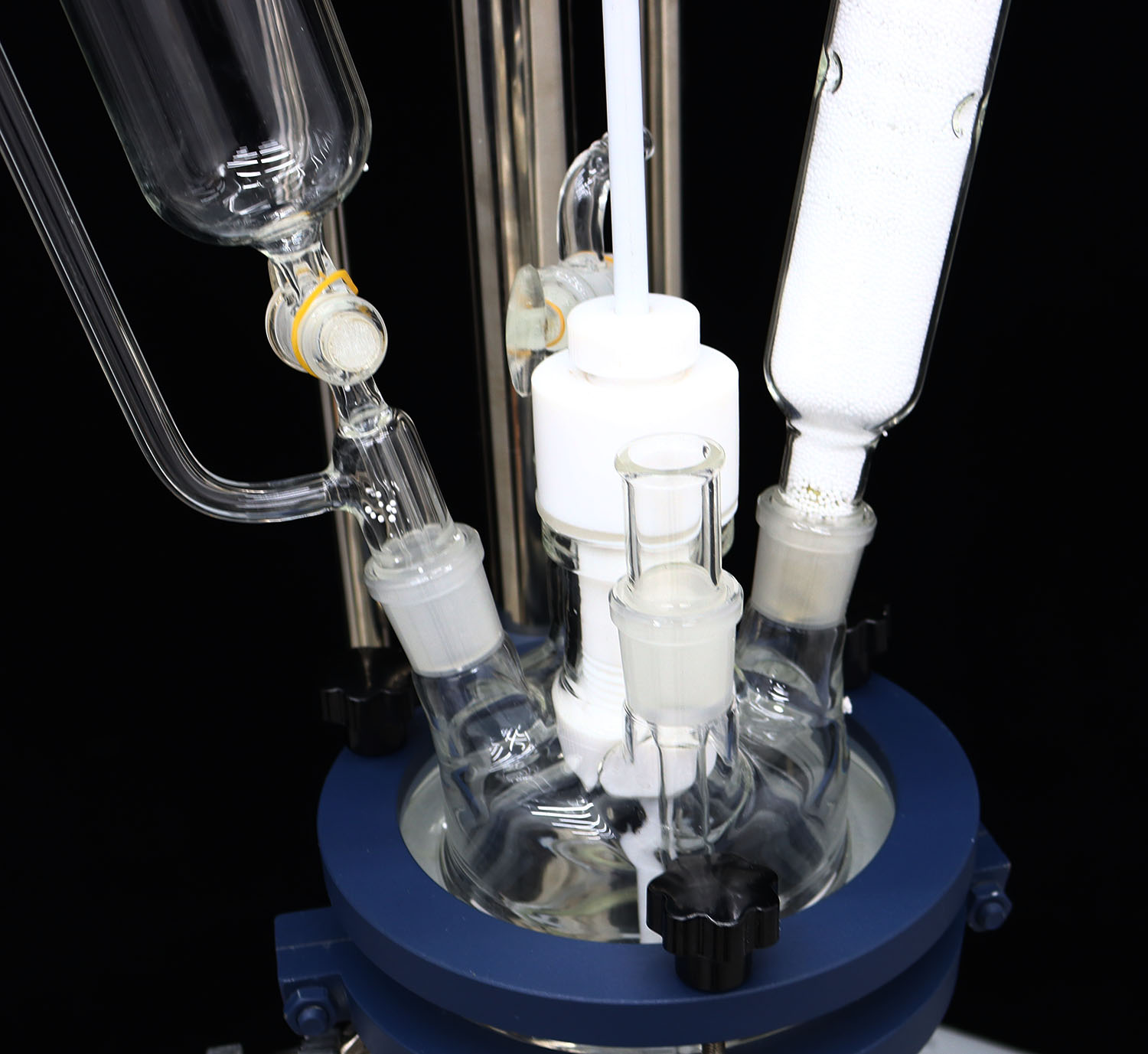

Instruction The inner layer container of the double-layer glass reactor is placed with the reaction material, and at the same time, vacuuming and speed stirring can be performed.The interlayer can be introuced into the chilled liquid, water and high temperature liquid to heat and cool the material, it is used in experiments, pilot tests and production of chemical, fine chemical, biopharmaceutical new material synthesis. the product can be combined with circulating water multi-purpose vacuum pump, circulating cooler, constant temperature circulator, low temperature coolant circulation pump, closed refrigeration heating cycle device (also known as high and low temperature circulation device). |

||||||||||||

|

Method of use

1. Plug in the power plug, turn on the power switch on the inverter, and use the speed control knob to select the appropriate speed. 2. The flow of materials and the power of the motor speed may resonate at a certain point. Please change the motor speed to avoid resonance. 3. After the stirring rod is installed, it must be rotated by hand, paying attention to whether the concentricity is good. If the concentricity is not good, loosen the heavy clamp, turn on the power after the clamp is correct, and gradually adjust from slow to fast. 4. Using the stirring rod regulator, the stirring leaf can be up and down 5cm as needed. 5. If you find that the sealing performance of the kettle has decreased, please check the rotating bearing in the agitator sleeve. 6. The interlayer on the glass kettle is connected to an external circulation port. Hot oil can be used for heating reaction, and cooling liquid can be used for low-temperature reaction. If steam heating is used, it should not exceed 0.5K-1K. (Try not to use pressure steam for heating). 7. When testing at low temperature, the discharge valve at the bottom will be frosted. When using the valve, it must be partially defrosted to prevent the glass from being broken. 8. If there are particulate objects in the solution during use, there may be leftovers on the PTFE piston of the valve during discharging. The air tightness will be affected when it is used again. Be sure to clean it after discharging each time and use it again. |

||||||||||||

|

Maintenance instructions

1.Check the instrument carefully before use. Whether the glass bottle is damaged and whether the interfaces are consistent. Be careful to handle it gently. 2. Wipe each interface with a soft cloth (can be replaced by a napkin), and then apply a little vacuum grease. (Vacuum grease must be covered after use to prevent dust and sand from entering.) 3. Each interface should not be tightened too tightly, and should be loosened regularly to avoid long-term locking and causing the connector to seize. 4. Turn on the power switch first, and then let the machine run from slow to fast. When shutting down, keep the machine in a stopped state, and then turn off the switch. 5. PTFE switches everywhere can't be tightened with excessive force, it is easy to damage the glass. 6. After each use, you must use a soft cloth to wipe off all kinds of oil stains, stains, and solvent remaining on the surface of the machine to keep it clean. 7. Loosen the PTFE switches after the machine stops, and the PTFE piston will be deformed if it is in the working state for a long time. 8. Clean the sealing ring regularly by removing the sealing ring, checking whether there is dirt on the shaft, wiping it with a soft cloth, then applying a little vacuum grease and reinstalling it to keep the shaft and the sealing ring smooth. 9. The electrical parts must not be exposed to water, and it is strictly forbidden to get wet. 10. When doing any repairs or inspections on the machine, be sure to cut off the power and water source first. |

||||||||||||

Parameter

|

||||||||||||

| Display | ||||||||||||

|

||||||||||||

|

||||||||||||

|

||||||||||||

|

||||||||||||

|

|

||||||||||||

Item Included

|

Paiement & Sécurité

Vos informations de paiement sont gérées de manière sécurisée. Nous ne stockons ni ne pouvons récupérer votre numéro de carte bancaire.